In today’s fast-paced industrial environment, the demand for efficient, dependable, and cost-effective machinery is greater than ever. Whether your business operates in manufacturing, food processing, pharmaceuticals, or any other sector that depends on compressed air systems, having the right technology is essential to maximizing productivity. At CoolAir Compressors, we specialize in delivering high-performance Chinese and European air compressors, along with state-of-the-art screw air compressors, industrial blowers, and vacuum pumps to cater to diverse industrial needs.

The Significance of Screw Air Compressors in Industrial Operations

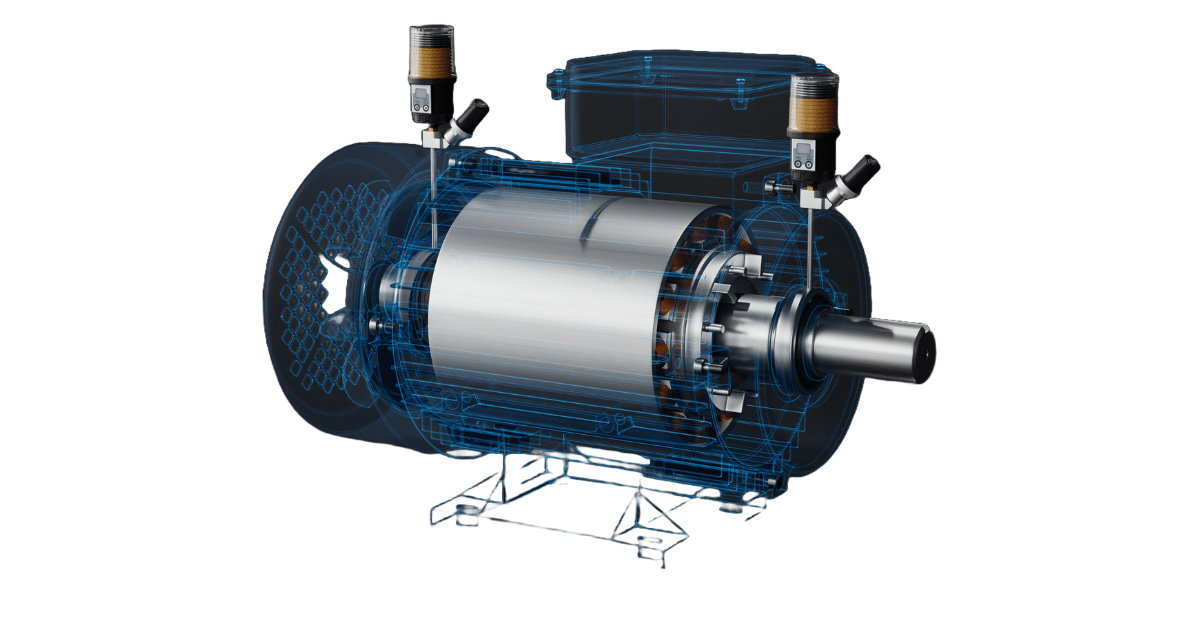

For processes that rely heavily on compressed air, screw air compressors stand out as one of the most reliable and energy-efficient technologies available today. Unlike piston compressors that use a back-and-forth piston motion, screw compressors operate with two interlocking helical screws to compress air continuously, ensuring consistent output without pressure fluctuations.

Key Benefits of Screw Air Compressors

-

Superior Energy Efficiency: Designed for continuous operation, screw compressors minimize energy losses, resulting in significant cost savings for industries needing uninterrupted airflow.

-

Low Maintenance Needs: With fewer moving parts and a sturdy design, these compressors are less prone to wear and tear, reducing maintenance time and costs.

-

Quiet Functioning: Compared to piston variants, screw compressors produce less noise, making them ideal for environments with strict noise control requirements.

-

Extended Equipment Life: Built to last, their robust structure ensures prolonged use with minimal downtime, making them a smart investment for long-term industrial use.

The Crucial Role of Blowers in Industrial Settings

Often underestimated, blowers are indispensable in numerous industrial systems — from waste treatment and HVAC to drying and material handling. These devices move air or gases at moderate pressure, supporting processes that require large volumes of airflow.

How Blowers Operate

Blowers typically work through either centrifugal force or positive displacement:

-

Centrifugal blowers use high-speed rotating impellers to move air outward through velocity conversion.

-

Positive displacement blowers push air by capturing and moving fixed volumes through enclosed chambers.

Why Blowers Matter:

-

Improved Air Circulation: Vital for maintaining ventilation and air purity, especially in enclosed workspaces.

-

Customizable Output: Can be tailored for various functions, whether for drying surfaces, cooling systems, or pneumatic transport.

-

Energy-Saving Solutions: Their efficiency in operation makes them a cost-effective option for large-scale air movement tasks.

Vacuum Pumps: A Core Element in Precision Industries

No overview of air management systems is complete without addressing vacuum pumps. These essential tools are used in industries like electronics, pharmaceuticals, and food processing where creating a vacuum environment is vital to product integrity.

What Vacuum Pumps Do

Vacuum pumps extract air and gases from sealed spaces to create low-pressure zones, which is critical for packaging, lifting, molding, and degassing processes.

Popular Types of Vacuum Pumps:

-

Rotary Vane Pumps: Ideal for general use in low to medium vacuum applications due to their durability and versatility.

-

Scroll Pumps: Known for their oil-free and quiet performance, they are suitable for clean environments like labs and electronics.

-

Diaphragm Pumps: Resistant to chemicals, these are perfect for handling aggressive or corrosive substances in laboratories and chemical plants.

Why CoolAir Compressors is Your Trusted Partner in Air Technology

At CoolAir Compressors, we are committed to delivering top-tier Chinese and European air systems. Our product range includes everything from high-capacity screw compressors to advanced vacuum pumps and industrial blowers — all carefully selected to meet the evolving needs of modern industries.

What Sets Us Apart:

-

Tailored Recommendations: We analyze your operational requirements and guide you toward the most appropriate solution.

-

Trusted Quality: We supply only from world-renowned manufacturers, ensuring lasting performance and minimal disruption.

-

Complete After-Sales Service: Our technical team offers full support — from system installation to scheduled maintenance — so your operations run smoothly without unexpected delays.

Final Thoughts

In industries where uptime and efficiency matter most, choosing the right air system technology is crucial. Whether your goal is to maintain steady compressed air through a screw compressor, ensure proper ventilation with a blower, or achieve precision control using vacuum pumps — CoolAir Compressors has the expertise and products to keep your operations efficient, reliable, and cost-effective.

Need more details? Get in touch today and let us help you optimize your air system needs.