The SLPM air compressor is powered by two independent IPM (Interior Permanent Magnet) motors, managed through an intelligent control system. During operation, it continuously adjusts the pressure between the two compression stages. By calculating the optimal rotation speeds for both air outlets, it ensures the best compression ratio and perfect balance. This allows the compressor to operate under optimal conditions at all times, maximizing energy efficiency and performance.In contrast, conventional two-stage compressors with fixed gear ratios can only achieve peak efficiency at a specific point. When operating with variable speeds and frequencies, they are unable to maintain the ideal inter-stage pressure. As a result, any speed reduction leads to energy consumption that is not synchronized with output, reducing overall efficiency.

The SLPM compressor is equipped with a high-performance IPM (Interior Permanent Magnet) motor, delivering excellent efficiency even at low frequency and low speed operations.

Unlike traditional geared two-stage systems that only achieve up to 97% transmission efficiency, the SLPM features a gearless, one-shaft design without couplings, ensuring:

100% Transmission Efficiency

Zero Transmission Loss

No Mechanical Wear from Gears or Couplings

This innovative structure guarantees consistent, energy-saving performance under all load conditions.

Thanks to its innovative design, the SLPM compressor ensures exceptionally quiet operation:

No Motor Bearing Noise

No Gearbox Noise

No Coupling Noise

With its gearless, one-shaft structure and IPM motor technology, mechanical friction and vibration are minimized—making the SLPM an ideal choice for noise-sensitive environments.

| Model | Motor Power (KW) | Working Pressure (Mpa) | Air Flow (m³/min) | Outlet Diameter | Size (L×W×H mm) | Weight (KG) |

|---|---|---|---|---|---|---|

| BPM-20A | 15 | 1.6 | 1.25 | 3/4″ | 1785×840×1800 | 540 |

| BPM-30A | 22 | 1.6 | 1.84 | 3/4″ | 1785×840×1800 | 600 |

| Model | Motor Power (KW) | Working Pressure (Mpa) | Air Flow (m³/min) | Outlet Diameter | Size (L×W×H mm) | Weight (KG) |

|---|---|---|---|---|---|---|

| AHB-10A | 7.5 | 1.6 | 0.48 | 1/2″ | 860×730×960 | 210 |

| AHB-15A | 11 | 1.6 | 0.65 | 3/4″ | 940×800×1075 | 260 |

| AHB-20A | 15 | 1.6 | 1.2 | 3/4″ | 940×800×1075 | 305 |

| AHB-30A | 22 | 1.6 | 1.75 | 1″ | 1200×950×1150 | 410 |

| AHB-50A | 37 | 1.6 | 3 | 1 1/2″ | 1500×990×1420 | 610 |

| AHB-60A | 45 | 1.6 | 4.3 | 1 1/2″ | 1500×990×1420 | 680 |

| AHD-75A | 55 | 1.6 | 5 | 1 1/2″ | 1500×990×1420 | 750 |

| AHD-100A | 75 | 1.6 | 6.4 | 2″ | 1800×1160×1490 | 870 |

| AHD-120A | 90 | 1.6 | 8.5 | 2″ | 1800×1160×1490 | 900 |

| AHD-150A | 110 | 1.6 | 10.7 | 2″ | 2100×1400×1780 | 1550 |

| AHD-175A | 132 | 1.6 | 14.5 | 2 1/2″ | 2500×1450×1800 | 2050 |

| AHD-220A | 160 | 1.6 | 18.2 | 2 1/2″ | 2500×1450×1800 | 2550 |

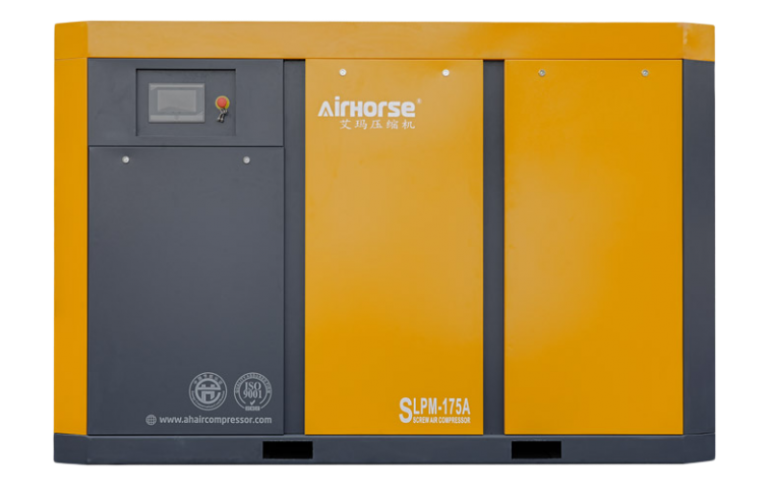

AirHorse ensure every machine Runs well more than 15 years

Stock Available + Very Quickly Effect Shipment

24 Hours Service Always at your service

Piping Material Features Comparison |

|||

| Piping Features | Stainless Steel(Type 304L) | Mild Steel | Blue anodized Aluminum Alloy |

| Weight (Dia 6inch, Length 6m) | 127.2 | 169.6 | 29.142 |

| Anti-Corrosive | Yes | No | Yes(100%) |

| Pressure drop (Dia 2 inch Length= 20m, Airflow=3 cubic metres/Minute, Pressure=10 bar) | 0.25 | 0.4 Bar | 0.1 |

| Efficient Energy Use | High | Low-moderate | High( Potential Cost savings of 34%) |

| Structural Durability | Very Strong | Very Strong | Strong |

| High Thermal Endurance | Yes | Yes | Yes |

| Installation Ease | Less Difficult | Difficult | Easy(High Flexibility and Modularity) |

| Simple Installation | Approx 6 feet length per hour | Approx 6 feet length per hour | Approx 45 feet Length per hour |

| Manpower and Work Hours Needed for 2″ Pipe Over 3000 Feet | Approx 600 man-hours/8 men for 2 weeks | Approx 600 man-hours/8 men for 2 weeks | About 100 man-hours with 8 workers, completed in under 2 days |

| Annual Charges for Installation, Commissioning & Operation | Approx 3000 dollars | Approx 7820 dollars | Approx 1300 dollars |

| Installation Cost Breakdown: Material % / Labor % | 30% / 70% | 25% / 75% | 80% / 20% |

| Texture of Surface | 0.03 | 0.05 | 0.001 |

| Required Specialized Tools: Welder, Threader, Groove Cutter | Yes | Yes | No |

| Quality of Air | High — When needed, these pipe systems comply with ISO 8573-1:2010 air quality standards | Low( Not according to !SO 8573-2010 air quality standards) | High — These pipe systems support compliance with ISO 8573-1:2010 air quality standards when required. |

| Cost Rate per Meter | Almost 2 less than Aluminum | 3 Times less than Aluminum | 163.64 Dollars |

| Service Life Depends on Environment, Pipe Design, and Grade | 30 years | 40 years | 20 years |

| Upfront Installation Cost | Material : 30% Labor:70% | Material : 25% Labor:75% | Material : 80% Labor:20% |

| Care and Maintenance | Difficult — Rust buildup under pipes and fittings can reach machinery, requiring weekly preventive maintenance. | Difficult (Accumulation of rust under pipes and fittings which travels to machinery may require preventive maintenance every 3-4 days) | Easy — No rust buildup, with preventive maintenance needed every 4 weeks. |